AM Finishing Page

As a leading provider of surface enhancement technologies, we help our customers to optimize build and finish strategy – delivering cost reduction and higher productivity.

As a leading provider of surface enhancement technologies, we help our customers to optimize build and finish strategy – delivering cost reduction and higher productivity.

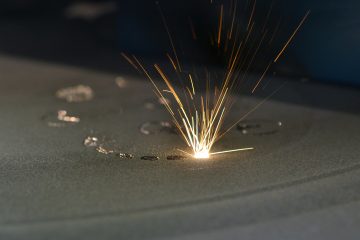

A leading provider in surface enhancement technologies for more than half a century, today we are committed to pushing the boundaries of AM. By providing class-leading AM services, combining in-house AM build with a profound knowledge of post processing and finishing technologies, the results become tangible: surface quality improvement, mechanical property enhancement, cost reduction, improved capacity and scalable productivity, to name a few.

We support our customers from primary projects phases. By combining the best practices in AM design with finishing in mind, Design-to-Build becomes Design-to-Finish. Simulating our processes upfront, we are able to guarantee the quality of results and ensure a process flow that is lean and free of bottlenecks.

Mastering the optimal balance between building and finishing strategy, we deliver a tangible cost reduction while improving quality and increasing productivity.

Support structure removal, elimination of partially-sintered material, surface finish for flow and fatigue improvement, simultaneous machining of internal and external irregular surfaces – thanks to our portfolio of technologies we can solve any of your AM challenges.

A passionate cross-functional, multi-disciplinary group of engineers is contributing to Extrude Hone Additive growth. Fearless vision and tireless work drive our daily commitment; trough continuous listening, we understand the inner needs and pains of our customers, and we strive to deliver solutions that exceed expectations. Building our reputation on customers success, we are proudly contributing to build next-generation products.

Flexible, scalable, certified. Leverage cutting-edge expertise without upfront investment.

Discover our T-Series equipment offering and technical specifications on the Extrude Hone website.